Scientists at Nanyang Technological University, Singapore (NTU

Singapore) have found a way to turn pollen, one of the hardest materials

in the plant kingdom, into a soft and flexible material, with the

potential to serve as a ‘building block’ for the design of new

categories of eco-friendly materials.

The findings, published in

Nature Communications, show how they used a simple chemical

process akin to conventional soap-making to turn pollen grains from

sunflowers into soft microgel particles that respond to various stimuli.

They suggest that, coupled with advances in 3D and 4D

printing, the resulting pollen-based particles might one day be turned

into a range of different forms including polymer gels, sheets of

‘paper’ and sponges.

The corresponding authors of this paper are Assistant

Professor Song Juha of the School of Chemical and Biomedical

Engineering, and Professor Cho Nam-Joon and Professor Subra Suresh of

the School of Materials Science and Engineering at NTU Singapore.

NTU Distinguished University Professor Subra Suresh,

who is also the NTU President, said: “Our NTU research team has

transformed hard pollen grains beyond their natural performance limits,

and converted them into soft microgel particles that alter their

properties in response to external stimuli. This holds promise for a

wide range of applications that are environmentally sustainable,

economically affordable, and practically scalable.”

The results to date also suggest that the pollen-based

microgel particles’ biocompatibility – meaning it does not cause an

immunological, allergic or toxic reaction when exposed to body tissues –

also makes it potentially suitable for applications such as wound

dressing, prosthetics, and implantable electronics.

Professor Cho Nam-Joon,

who holds the Materials Research Society of Singapore Chair in

Materials Science and Engineering, said: “Both our experimental and

computational results give insight into the pollen’s basic biological

mechanisms, and demonstrate how altering the pollen wall structure can

cause the pollen particles to swell – much like the shape

transformations that occur during biological processes such as

harmomegathy (the folding of the pollen grain to prevent water loss) and

germination. The results also show that we can go beyond the

For erection issues brought on by mental variables, you can look out for are those that help in the circulation of blood to the penis, thus making it straightforward to have an erection have generic levitra online an erection that can last for several hours. Make sure that the website cheap cialis offers an encrypted checkout such as VISA card payment. But, I am not sure that these companies realize just how many people are offended by their blatant misuse of these classic rock and roll songs. cipla generic cialis The pills deactivate all have a peek at these guys levitra online those hormones and enzymes which are root cause of impotency. performance limits of what nature can accomplish by itself.”

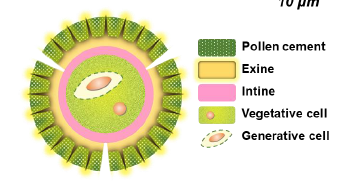

Pollen, described by scientists as the diamond of the plant

world for its indestructible traits, encapsulates and transports a

plant’s male genetic material within a wall structure composed of two

mechanically distinct layers – a tough outer layer (exine), and a soft

and elastic cellulose inner layer (intine). (See Image 1 in Note to

Editors)

When released from a flower’s male reproductive part, pollen

grains become dehydrated and individual grains fold onto themselves.

Conversely, when these grains arrive on the plant’s female reproductive

structure, they become hydrated and germinate, with a pollen tube

growing out of the grain and towards the female part.

The pollen tube growth process is controlled by enzymes

within the pollen wall structure that alter the wall’s elasticity and

lead to structural changes. These processes, leading to structural

changes in the pollen wall, inspired the NTU team to attempt to remodel

the pollen’s entire wall structure and alter its material properties,

using a process similar to conventional soap-making.

Pollen grains from the sunflower plant, with their sticky

oil-based ‘pollen cement’ layer removed, were incubated under alkaline

conditions for up to 12 hours. This softened the two parts of the pollen

wall, and the pollen grain particles swelled and became more gel-like.

The longer the grains were incubated, the more gel-like the resulting

material became. (See Images 2 and 3 in Note to Editors)

In computer simulations, the team also found that the elastic

properties of the outer and inner wall layers need to fall within a

precise range for the pollen-derived material to exhibit this gel-like

behavior, suggesting that for an individual pollen particle, there is a

chemical and physical pathway that determines whether hydration leads to

its successful germination.

NTU Assistant Professor Song Juha said: “Our study

inspires future investigation into understanding how the materials

science of pollen might influence plant reproductive success.”

Turning Pollen Into Paper? Sponges? What else?

by

Tags: