Highlights

•

Alcohol can be fermented from the starch of peas (Pisum sativum L.) instead of wheat.•

Gin produced from peas had a smaller environmental footprint for 12 impact categories.•

Protein rich co-products of gin production substitute soybean and barley animal feed.•

Animal feed substitution more than offsets the carbon footprint of pea gin.•

Pea gin has a larger land footprint than wheat gin, depending on rotation effects.

Abstract

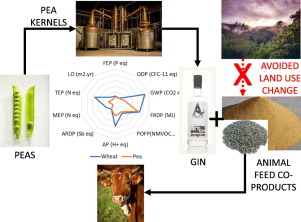

Industrialised agriculture is heavily reliant upon synthetic nitrogen fertilisers and imported protein feeds, posing environmental and food security challenges. Increasing the cultivation of leguminous crops that biologically fix nitrogen and provide high protein feed and food could help to address these challenges. We report on the innovative use of an important leguminous crop, pea (Pisum sativum L.), as a source of starch for alcohol (gin) production, yielding protein-rich animal feed as a co-product. We undertook life cycle assessment (LCA) to compare the environmental footprint of 1 L of packaged gin produced from either 1.43 kg of wheat grain or 2.42 kg of peas via fermentation and distillation into neutral spirit. Allocated environmental footprints for pea-gin were smaller than for wheat-gin across 12 of 14 environmental impact categories considered. Global warming, resource depletion, human toxicity, acidification and terrestrial eutrophication footprints were, respectively, 12%, 15%, 15%, 48% and 68% smaller, but direct land occupation was 112% greater, for pea-gin versus wheat-gin. Expansion of LCA boundaries indicated that co-products arising from the production of 1 L of wheat- or pea-gin could substitute up to 0.33 or 0.66 kg soybean animal feed, respectively, mitigating considerable greenhouse gas emissions associated with land clearing, cultivation, processing and transport of such feed. For pea-gin, this mitigation effect exceeds emissions from gin production and packaging, so that each L of bottled pea gin avoids 2.2 kg CO2 eq. There is great potential to scale the use of legume starches in production of alcoholic beverages and biofuels, reducing dependence on Latin American soybean associated with deforestation and offering considerable global mitigation potential in terms of climate change and nutrient leakage — estimated at circa 439 Tg CO2 eq. and 8.45 Tg N eq. annually.

Graphical abstract

Previous article in issueNext article in issue

Keywords

PeaLegumesLife cycle assessmentLCAAnimal feedDDGSDistillationEthanol

1. Introduction

Industrialised agriculture systems are heavily dependent on the application of synthetic nitrogen (N) fertiliser, around half of which is not assimilated by the target crop but lost to the environment. Leaching of N into water courses and gaseous emissions of NH3, NOx and N2O drive eutrophication of waters, pollution of air, acidification of aquatic and terrestrial systems and climate change (Sutton et al., 2011; Pinder et al., 2012). Direct economic costs of N losses are estimated at €320 billion yr−1 for the EU alone (Sutton et al., 2011). The IPCC 5th Assessment report (IPCC, 2015) has highlighted the importance of more sustainable consumption combined with improved N use efficiency to reduce greenhouse gas (GHG) emissions.

Legumes are a type of crop which require no synthetic N fertiliser owing to their capacity for biological nitrogen fixation (BNF), a process which converts inert atmospheric N2 molecules into biologically useful N-forms (Sprent and Sprent, 1990). Life cycle assessment (LCA) studies have demonstrated that legumes can reduce GHG emissions in arable rotations compared with cereals and other crops that depend on synthetic N fertiliser (Nemecek et al., 2008, Nemecek et al., 2015). The introduction of legumes into cereal-dominated rotations can deliver a plethora of other ecosystem service benefits, including enhanced soil quality and support for pollinating insects (Crews and Peoples, 2004; Jensen et al., 2012; Raseduzzaman and Jensen, 2017; Stagnari et al., 2017; Peoples et al., 2019). Legumes are also rich in protein and fibre, providing nutritious food for humans or feed for animals. However, grain legume cultivation, primarily peas (Pisum sativum L.) and faba bean (Vicia faba L.), occupies just 1.5% of arable land in the European Union (EU) (Watson et al., 2017); insufficient to support significant BNF or ecosystem services delivery at landscape scale (Iannetta et al., 2016). Meanwhile, there is growing concern about Europe’s dependence on imports to meet 70% of protein-feed fed to pigs, poultry, cattle and fish (Thomassen et al., 2008; de Visser et al., 2014; De Santis et al., 2016; Watson et al., 2017; European Commission, 2018b), in particular milled grains of the legume soybean (Glycine max L). Soybean cultivation in Latin American exporting countries drives environmental damage, including rainforest destruction (Persson et al., 2014). Thus, there is strong interest in substitution of soy-based feeds to improve the sustainability and resilience of European livestock and expanding aquaculture systems (Hortenhuber et al., 2011; Schader et al., 2015; De Santis et al., 2016).

Nevertheless, a challenge remains to make home-grown legumes more profitable against inexpensive imported soybean, and against other home-grown, but synthetic-N-fertiliser-dependant, commodities such as cereals and oil seeds widely used for food, feed and biofuels (Iannetta et al., 2016). Legume profitability may be improved by increased demand for plant proteins in the human diet following recent trends driven by health and sustainability concerns (Foyer et al., 2016; Willett et al., 2019). A potentially more scalable approach to increase the commercial potential of legume grains is the substitution of cereals in existing food, feed and biofuel value chains. The starch fraction of legumes can substitute cereal starch in e.g. bread, pasta and alcohol production. Previous studies have highlighted the important role of a by-product from alcohol production, dried distillers’ grains with solubles (DDGS), as a highly-digestible, protein-rich animal feed that can substitute soybean derived feeds and thus avoid significant environmental impact (Hortenhuber et al., 2011; Weightman et al., 2011; Leinonen et al., 2018). Legume substitution of cereals in alcohol production could enhance this benefit by elevating the protein content of these by-products.

The research we report here evaluates the use of peas instead of wheat to make neutral spirit for gin, considering the possible consequences of increased protein content in the DDGS co-product. The analysis is based on data generated from pilot studies carried out at Arbikie Distillery on the East Coast of Scotland. Gin production provides a pertinent case study, as it is a high-value product subject to rapidly increasing demand globally. In 2017, 377 million L of gin were produced by the eight largest gin brands (Statista, 2019). The gin production process first requires the production of neutral spirit (through the steps of milling, mashing, fermentation and distilling) prior to redistilling in the presence of botanicals to flavour the spirit. The brewing and distillation processes involved are widely deployed across other products, including whisky, vodka, beer and industrial bioethanol (biofuel) production – implying high scalability and impact from this innovative use of legume starch.

2. Materials and methods

2.1. Goal, scope and boundary definition

This study is based on operational data provided by Arbikie distillery in Scotland, from records generated during routine operations producing conventional wheat-gin and during pilot trials for pea-gin production. Owing to the importance of synthetic fertiliser-N use offset due to high-N pea residues (stems, pods and root systems) left in-field after grain harvest, and the potential use of the high-protein pot-ale co-product comprising suspended solids (of pea or wheat) that may serve as an animal feed, we applied an attributional LCA (Finkbeiner et al., 2006) with expanded boundaries (Styles et al., 2018a, Styles et al., 2018b) (Fig. 1). The functional unit was one L of gin at the distillery gate, bottled in 700 mL bottles and packaged in cardboard boxes ready for distribution. Expanded boundaries encompassed: (i) cultivation of wheat or pea crops; (ii) de-hulling of peas and milling of pea kernels and wheat grain into grist; (iii) distillery operations; (iv) gin bottling and packaging for distribution; (v) management of pot-ale as either land-spread fertiliser or animal feed, processed into DDGS for the latter use; (vi) credits for avoided production, transport (and application) of synthetic N fertilisers and avoided animal feed (soy bean and barley); and (vii) avoided land use change from spared soybean meal, and incurred land use change from net additional UK cropland requirements (for pea gin compared with wheat gin). The production and transport of all material and energy inputs (Fig. 1) were accounted for, but the construction or manufacture of infrastructure and capital equipment was excluded (BSI, 2011). All field emissions associated with crop cultivation and residue incorporation, and with land spreading of pot-ale, were accounted for.

A secondary objective was to test the influence of different LCA boundary definitions on the results. Accordingly, we also applied a simple attributional LCA in which pot-ale was treated as a waste and all co-products were allocated away from gin system burdens to produce a simple environmental footprint of gin (Fig. 1). Environmental burdens were reported across 14 impact categories recommended for the Product Environmental Footprint standard (JRC, 2018), and allocation was based on respective gross energy flows. Sensitivity analyses were undertaken to account for different management decisions within the expanded boundary value chain that were likely to significantly influence LCA results (Table 1). Additional detail on methodology, and full results of all sensitivity analyses, are presented in an accompanying “Data in Brief” article (Lienhardt et al., 2019).

Table 1. Scenario permutations for co-product and waste handling in gin produced from wheat or peas, including permutations pertaining to wheat-only (W) or pea-only (P). Relevant scenarios were analysed using a confined boundary attributional LCA (A) and an expanded boundary LCA (E) approach, as defined in Fig. 1. Permutations highlighted in bold are presented in the Results and discussion section; other permutations are presented in supplementary results (Tables 12–15 in Lienhardt et al., 2019).

| Scenario | Straw exported (W) | Pea hull use (P) | Pot-ale mgt | Fert-N-subresidue | Fert-subpot-ale | Soya subDDGS | Soya sub hulls (P) | Land use change (P) | LCA method |

|---|---|---|---|---|---|---|---|---|---|

| Ginbase | No | Cattle feed | Land spread | No | No | No | Yes | No | A |

| Yes | Cattle feed | Land spread | No | No | No | Yes | No | A | |

| Gin+fert | No | Cattle feed | Land spread | Yes | Yes | No | Yes | Yes | E |

| Yes | Cattle feed | Land spread | Yes | Yes | No | Yes | Yes | E | |

| Gin+feed | No | Cattle feed | Cattle feed, DDGS | Yes (E) | No | Yes | Yes | Yes | A&E |

| Yes | Cattle feed | Cattle feed, DDGS | Yes (E) | No | Yes | Yes | Yes | A&E |

Notably, wheat straw may be incorporated back into the soil or exported as a co-product, with implications for residue incorporation (emissions, leaching and synthetic N fertiliser substitution) and share of cultivation burdens allocated to the grain used for gin production (Fig. 1). We accounted for both options, conservatively assuming straw harvest and allocating grain burdens accordingly for primary results benchmarking the environmental footprint of pea gin (Table 1). Residues returned to the soil from wheat and pea cultivation contain a significant amount of N, a fraction of which substitutes fertiliser-N in following crops. This effect is captured in the expanded boundary LCA (Fig. 1; Table 1).

Hulls from dried combining peas are separated from kernels prior to milling, providing a valuable and easy-to-handle source of animal feed (Hodmedod’s, 2018). Use of pea hulls for cattle feed was represented by allocation of cultivation and processing burdens in simple attributional LCA, and by avoidance of soybean and barley production and transport in the expanded boundary LCA (Fig. 1; Table 1). Pot-ale generated by the Arbikie distillery is currently stored in a large tank and spread on fields as a fertiliser, which we represent in Gin+fert using an expanded boundary LCA in which the potential synthetic fertiliser substitution achieved by pot-ale is accounted for as a credit. In the Ginbase simple attributional LCA, land spreading of pot ale is considered as a waste management practise, and associated emissions are included in the gin footprint without subtracting any credit for fertiliser substitution. Alternatively pot-ale may be used locally as an animal feed, or dried and processed into DDGS, a more versatile and valuable animal feed that can be transported longer distances — in both cases potentially substituting soybean as the marginal high-protein animal feed in Europe (Schmidt, 2008; Hortenhuber et al., 2011; European Commission, 2018a) and barley as the marginal energy-feed (Leinonen et al., 2018). To generate footprints based on simple attributional LCA for the Gin+feed scenarios, all burdens up to the point of gin production were allocated between gin and pot-ale. For the expanded boundary LCA of Gin+feed scenarios, all system burdens were allocated to gin, including pea hull and all DDGS processing and transport, whilst avoided production and transport of soybean meal and barley grain were treated as avoided burdens (i.e. credits) (Table 1). Soybean meal and barley grain credits were derived from LCA data on the typical market mix of these products extracted from Agrifootprint v4.0 (Blonk Consultants, 2019) and Ecoinvent v3.5 (Wernet et al., 2016), respectively. The data included average land use change burdens for these feed commodities.

2.2. Wheat gin inventory

There are three steps in the distillation process to make gin that is marketed at 43% alcohol by volume. First, grain is ground and mixed with hot water to solubilise the starch which, via enzyme action, is degraded to produce to a sugary liquid (wort). Spent grains from the mash are sent to a pot ale storage tank. Second, cooled wort is sent to a fermentation vessel where yeast is added. This converts the sugars to ethanol and carbon dioxide, producing the wash with an alcohol content around 10% (v/v). The third step is distillation – the wash is distilled first to low wines, containing 20–30% alcohol, then to neutral spirit comprising 96% alcohol. A third distillation in the presence of juniper and other botanicals follows to flavour the spirit in to gin which is then diluted down to bottling strength (43% ABV). During the neutral spirit and gin distillations the spirit is collected in three portions, the first and last being discarded.

Table 2 summarises the main inputs and outputs across the nine value chain stages considered in this study, from crop cultivation through distillation and gin packaging to animal feed substitution. Activity data (e.g. grain, energy, water and enzyme inputs and gin yields) were primarily provided by Arbikie Distillery in Scotland from commercial operations using wheat as a feedstock, and pilot trials using pea grist as a feedstock. Mass balances were derived for carbohydrate (primarily starch) and protein flows in the production of one batch (1886 L) of gin from either wheat or peas, as detailed in Lienhardt et al. (2019). For one batch of gin, 2706 kg dry matter (DM) of wheat grain is required, resulting in 10,547 L of pot ale containing 1092 kg DM and 341 kg protein, and producing 1159 L alcohol in the wash (Table 2 in Lienhardt et al., 2019). The alcohol yield is within 2% of the specific wheat-alcohol yield reported by Kindred et al. (2008). Data provided by Arbikie on wheat cultivation on the estate were used to parameterize the wheat cultivation inventory (Tables 2 and 5 in Lienhardt et al., 2019), based on a grain yields of 7430 kg ha−1 and a synthetic fertiliser-N input of 163 kg ha−1, similar to average UK wheat production (Styles et al., 2015). Transport data for botanical and packaging ingredients (Table 2) were obtained from questionnaires and phone conversations with supply companies including Beacon commodities (botanicals), Erben (packaging for bottles), Saverglass (bottles), Lallemand (yeast), SPL international (enzymes) and Saica pack (cartons).

Table 2. Inventory of inputs and outputs for a reference flow of one batch (1886 L) of gin made from either wheat or peas.

| Stage | Input/output/process | Units | Wheat | Pea |

|---|---|---|---|---|

| In | Out | In | Out | |

| Cultivation | Fertiliser ammonium-N | kg | 44 | 0 |

| Fertiliser urea-N | kg | 18 | 0 | |

| Fertiliser P2O5 | kg | 17 | 39 | |

| Fertiliser K2O | kg | 25 | 20 | |

| Lime | kg | 209 | 245 | |

| Diesel | kg | 85 | 52 | |

| Seed man & trans | kg | 27 | 123 | |

| Agrochemical input | 2 | 1 | ||

| Land | m2 | 4182 | 9811 | |

| Grain (dry matter) | kg | 2703 | 4011 | |

| Straw (dry matter) | kg | 1871 | 0 | |

| Residue N (incorporated) | kg | 23⁎ | 58 | |

| Processing & transport | 16–32 t truck | t·km | 236 | |

| De-hulling electricity | kWh | 235 | ||

| Pea grist | kg | 2782 | ||

| Trans to distillery, 16–32 t truck | t·km | 16 | 139 | |

| Hull processing (for cattle feed) | Hulls (mass pellet produced) | kg | 1777 | |

| Hulls transport, 16–32 t truck | t·km | 123 | ||

| Pelleting energy | kWh | 172 | ||

| Pellet transport, 16–32 t truck | t·km | 89 | ||

| Mashing & fermentation | Grain/grist input (dry matter) | kg | 2703 | 2782 |

| Product water | L | 11,704 | 11,704 | |

| Oil for heating | L | 143 | 143 | |

| Enzyme trans, 16 t truck | t·km | 2 | 2 | |

| Enzyme trans, van | t·km | 0 | 0 | |

| a-Amylase | kg | 1 | 1 | |

| Glucoamylase | kg | 3 | 3 | |

| Yeast man | kg | 14 | 14 | |

| Yeast trans, 16 t truck | t·km | 9 | 9 | |

| Yeast trans, van | t·km | 2 | 2 | |

| Distillations & flavouring | Oil for heating | L | 870 | 870 |

| Electricity | kWh | 946 | 946 | |

| Product water | L | 1000 | 1000 | |

| Juniper | kg | 15 | 15 | |

| Juniper trans, sea | t·km | 0 | 0 | |

| Juniper trans, >32 t truck | t·km | 25 | 25 | |

| Juniper trans, van | t·km | 2 | 2 | |

| Coriander | kg | 8 | 8 | |

| Coriander trans | t·km | 7 | 7 | |

| Product water | L | 1000 | 1000 | |

| Bottling & packaging | Bottles man | kg | 1905 | 1905 |

| Bottles trans, >32 t truck | t·km | 2221 | 2221 | |

| Plastic cork mans | kg | 4 | 4 | |

| Cork trans | t·km | 9 | 9 | |

| Steel caps man | kg | 15 | 15 | |

| Caps trans, > 32 t truck | t·km | 12 | 12 | |

| Cartons man | kg | 110 | 110 | |

| Cartons trans, > 32 t truck | t·km | 15 | 15 | |

| Pot-ale spreading | Pot ale storage | L | 10,547 | 10,547 |

| Pot ale trans, tractor-trailer | t·km | 53 | 53 | |

| Pot-ale spreading | m3 | 11 | 11 | |

| Or, pot-ale processing to DDGS | DDGS process heat (oil or gas) | kWh | 185 | 230 |

| DDGS process electricity | kWh | 16 | 20 | |

| DDGS transport, > 32 t truck | t·km | 109 | 136 | |

| DDGS produced | kg | 1213 | 1514 | |

| (Avoided animal feed) | Avoided soybean meal (hulls) | kg | NA | −547 |

| Avoided barley grain (hulls) | kg | NA | −842 | |

| Avoided soybean meal (DDGS) | kg | −628 | −1696 | |

| Balancing barley grain (DDGS) | kg | −569 | +300 | |

| (Avoided fertilisers) | Avoided ammonium-N fertiliser (residues) | kg | −11⁎ | −33 |

| Avoided ammonium-N fertiliser (pot ale) | kg | −27 | −59 | |

| Avoided P2O5 fertiliser (pot ale) | kg | −20 | −25 | |

| Avoided K2O fertiliser (pot ale) | kg | −22 | −27 |

⁎

When straw incorporated. Negative values = avoided inputs.

All burdens associated with production and transport of inputs (e.g. fertilisers, oil-heat, glass bottles, soybean) were extracted from Ecoinvent v.3.5 (Wernet et al., 2016) using OpenLCA v1.7.4. Synthetic N fertiliser substitutions from pot-ale spreading and residue incorporation were estimated using the MANNER-NPK model (Nicholson et al., 2013), and an assumption that 50% of residue-N is available for uptake by subsequent crops in the rotation over the long term (Preissel et al., 2015), respectively, further elaborated in Lienhardt et al. (2019). Field emissions of CO2, N2O, NH3, N and P leaching were calculated for cultivation, subsequent residue incorporation, land application of pot-ale and substituted fertilisers, as per the methods reported in Styles et al., 2018a, Styles et al., 2018b. In brief, CO2 and N2O emissions were calculated using an IPCC Tier 1 approach (IPCC, 2006), whilst NH3 emissions and N leaching were calculated based on national inventory emission factors (Misselbrook et al., 2015; Duffy et al., 2018) and MANNER-NPK (Nicholson et al., 2013). Pot-ale may be transported in tankers to neighbouring farms for use as an animal feed or processed into more versatile and valuable DDGS which can be used on dairy and beef farms (Table 1). We assumed that unprocessed pot-ale was transported 5 km by liquid tanker for processing into DDGS. Energy required for mechanical and heat drying of pot ale for conversion into DDGS was based on Murphy and Power (2008). DDGS was then transported an average distance of 100 km to cattle farms where it substituted soybean meal and barley grain according to respective crude protein and metabolizable energy contents. The protein content of wheat- and pea- DDGS was based on the mass balances presented in Lienhardt et al. (2019), whilst metabolizable energy values and crude protein contents for the other cattle feeds were obtained from Feedipedia (INRA, CIRAD and FAO, 2019). As per Leinonen et al. (2018), we employed linear programming optimisation, using the solver function in MS Excel, to calculate the precise quantities of soybean meal and barley substituted by pea hulls and DDGS from wheat and pea gin in order to balance crude protein and metabolizable energy supply, elaborated in Lienhardt et al. (2019).

2.3. Pea gin inventory

The inventory for pea-gin is identical to that for wheat-gin from fermentation through to packaging. Based on Arbikie pilot trials, one batch of gin (1886 L) requires a pea grist input of 2782 kg DM, produced from 4558 kg DM combining peas (Table 3 in Lienhardt et al., 2019). De-hulling and milling of peas produces 1777 kg hulls as a co-product. These are transported 100 km to a feed mill, where they are pelleted and transported a further 50 km to a cattle farm where they replace soybean and barley feed based on a total protein content of 330 kg and a total energy content of 15,635 MJ (Table 7 in Lienhardt et al., 2019). Pot-ale arising from gin production using pea kernels also contains over twice as much protein as pot-ale arising from wheat-gin, at 743 kg protein per batch (Lienhardt et al., 2019). Thus, a total of up to 1243 kg soybean meal plus 541 kg (net) barley are substituted in the pea-gin value chain compared with up to 628 kg soybean meal plus 569 kg barley substituted in the wheat gin value chain (Table 2), for Gin+feed scenarios (Table 1). The difference in UK land occupation for pea cultivation versus wheat cultivation per batch of gin, minus avoided barley area, was represented as the area of possible UK land use associated with pea gin production, and multiplied by European cropland land use change burdens taken from Ecoinvent v3.5 (Wernet et al., 2016). Meanwhile, a higher N content in pea residues and in pot-ale arising from pea gin production results in respective synthetic N fertiliser substitutions of up to 76 and 38 kg from the pea- and wheat-gin value chains, respectively for the Gin+fert scenario (Table 2). Pea nutrient values and processing data were obtained from pea processors (Hodmedod’s, 2018).

Table 3. Summary results per functional unit (1 L bottled and packaged gin), for gin produced from wheat or peas, per pot-ale management scenarios and LCA methodologies (as summarised in Table 1). This assumes wheat straw is exported in all but the Gin+fert scenarios. Environmental burdens for pea-gin have been shaded green, orange or red where they are significantly lower, the same or higher (respectively) than burdens for wheat gin.

No published studies were found against which to compare alcohol yields from pea kernel, but the specific alcohol yield reported by Arbikie is within 7% of the yield expected from stoichiometric conversion of all carbohydrate (Pietrzak et al., 2016). To represent possible variability and uncertainty in the alcohol yield from pea kernels, we undertook a set of sensitivity analyses by repeating all calculations based on a 30% higher input of pea kernels to the process, representing an equivalent carbohydrate input to the fermentation process from pea kernels as from wheat grain (Table 4 in Lienhardt et al., 2019).

2.4. Impact assessment & interpretation

Life cycle impact assessment was undertaken according to the suite of assessment methods proposed by the European Product Environmental Footprint (PEF) initiative (Castellani et al., 2018) within Open LCA v.1.7.4 and through application of relevant characterisation factors to field emissions (see Tables 8–11 in Lienhardt et al., 2019). Fourteen impact categories were considered, including a cropland appropriation indicator (m2 y−1) derived from inventory data to represent allocated cropping areas for wheat, pea and (avoided) soybean and barley production. Full results are presented in Tables 12–15 of Lienhardt et al. (2019), and summary results are presented in the main body of this paper for the following key impact categories: global warming potential (GWP), expressed as kg CO2 eq.; freshwater eutrophication potential (FEP), expressed as kg P eq.; marine eutrophication potential (MEP), expressed as kg N eq.; acidification potential (AP), expressed as mmol acid eq.; land occupation potential (LO), expressed m2 yr−1; resource depletion potential (RDP), expressed as MJ eq. These represent some of the major global environmental sustainability challenges (Rockström et al., 2009; Steffen et al., 2015) strongly influenced by food and drink value chains (Poore and Nemecek, 2018). Indicator scores were also normalised against average global per capita loadings (Castellani et al., 2018) in order to compare dimensionless normalised scores across impact categories.

Sensitivity analyses were undertaken to account for some of the potential variations in management likely to have a significant influence on the footprint of gin, especially regarding wheat straw harvest and pot ale management (Table 1). One of the most influential sources of uncertainty is the alcohol yield obtained from pea kernels, and as mentioned previously we reduced this by 30% from values observed in pilot trials in order to identify the sensitivity of footprint results to this factor (Table 11 in Lienhardt et al., 2019).

3. Results and discussion

3.1. Simple attributional LCA

The simple allocated footprint of gin production in the Ginbase scenario is very similar for wheat- and pea-gin, at 3.2 and 3.1 kg CO2 eq. L−1, respectively (Table 3). Normalised results (Fig. 2) indicate that the environmental impact categories to which gin production contributes most significantly are global warming, fossil resource depletion, acidification, terrestrial eutrophication and land occupation, reflecting crop cultivation, nutrient cycling and fossil fuel (especially oil heating for distillation) processes (Fig. 3). Cultivation is the major source of eutrophication and acidification burdens (for wheat gin) and for land occupation, whilst oil heating and production of packaging materials, primarily glass, are the major sources of global warming and fossil resource depletion (Fig. 3). Transport burdens, embodied within pre-processing, enzymes and flavourings and packaging categories in Fig. 3, are minor. Thus, the 23-fold greater amount of pre-processing transport required for peas compared with wheat (to bring them to a processing plant for de-hulling and milling: Table 2) did not manifest as large pre-processing burdens (Fig. 3).

In the most conservative baseline scenario where pot-ale is treated as a waste and system burdens are allocated across wheat straw and pea hull co-products, gin produced from peas has a smaller environmental footprint than gin produced from wheat across ten of the 14 impact categories considered (Table 3; Fig. 2). Notably, global warming, terrestrial eutrophication and acidification burdens are, respectively, 4%, 66%, 43% and lower for pea-gin compared with wheat-gin. These differentials improve to 9%, 73% and 52% if wheat cultivation burdens are allocated off to straw (Table S5.1). The main trade-off for pea gin is considerably (124%) higher land occupation, at 3.6 m2·yr per L gin produced (Table 3; Fig. 2), reflecting significantly lower grain yield for peas than wheat (4810 vs 7430 kg ha−1 yr−1) and allocation of 27% of wheat cultivation area to wheat straw. Sensitivity analyses indicate that increasing the amount of pea kernels required for fermentation so that the amount of carbohydrate is equivalent to that of wheat would result in pea gin burdens increasing by 1% (ionising radiation) to 30% (land occupation) in the Ginbase scenario (Table 12 in Lienhardt et al., 2019). Pea gin would have larger burden than wheat gin across six of the 14 impact categories assessed.

Allocating system burdens between gin and DDGS used as animal feed on an energy basis results in average burden reductions of 26% and 32%, for wheat and pea gin respectively (Table 3; Fig. 2). Pea gin has lower allocated environmental burdens than wheat gin across 12 of the 14 impact categories in the Gin+feed scenario (Table 3). For example, following feed allocation, the carbon footprint of pea gin shrinks from 3.1 (Ginbase) to 2.2 kg CO2 eq. L−1, versus a decline from 3.2 to 2.5 kg CO2 eq. L−1 for wheat gin. This is due to the relatively greater amount of animal feed contained in the pot-ale produced from pea kernels compared with pot-ale produced from wheat (Table 2, Table 3 in Lienhardt et al., 2019). However, land occupation remains 112% greater, at 2.6 m2.yr/L, for pea gin compared with wheat gin. Pea gin burdens are not sensitive to alcohol yields in the Gin+feed scenario owing to allocation of system burdens to larger quantities of feed co-product when alcohol yields are lower (Table 13 in Lienhardt et al., 2019).

3.2. Expanded boundary LCA

Boundary expansion generated significant environmental credits for avoided fertiliser manufacture and for avoided soybean meal production, especially for the more protein- (and N-) rich residues and co-products arising from the pea-gin value chain in the Gin+fert scenario (Fig. 3). Accounting for use of pea hulls as cattle feed and pot-ale as an organic fertiliser through boundary expansion, and incorporating wheat straw rather than allocating off a share of wheat cultivation burdens to exported straw, results in pea gin having a smaller environmental footprint than wheat gin across 13 of the 14 impact categories in the Gin+fert scenario (Table 3). In particular, the carbon footprint of pea gin is reduced to just 1.1 kg CO2 eq. L−1 owing to substantial “credits” associated with substitution of fertilisers and soybean meal as an animal feed (Fig. 3). This reflects the high carbon footprint of avoided soybean meal (4.83 kg CO2 eq. kg−1), which includes average land use change GHG emissions attributable to the market mix of soybean meal originating from major exporting countries (Blonk Consultants, 2019). However, land occupation remains 95% higher for pea-gin than for wheat-gin (4.3 versus 2.2 m2 yr/L, respectively), even after accounting for avoided soybean and barley feed production. This is because only 31% of the pea protein yield ends up in the pea hulls that substitute animal feed in the Gin+fert scenario, and, owing to the nutritional characteristics of the hulls, a large share of this protein is compensated for by barley grain produced with a grain yield of 6485 kg DM ha−1 yr−1 (Wernet et al., 2016), compared with the average pea yield of 4089 kg DM ha−1 yr−1 (PGRO, 2017). Net pea gin burdens in the Gin+fert scenario were sensitive to a reduction in the alcohol yield of pea kernels, reflecting variable changes in the balance between increased burdens (e.g. for cultivation) and larger credits from greater substitution of soybean and barley feeds per L of alcohol produced (Table 14 in Lienhardt et al., 2019). Thus, at lower alcohol yield, net burdens per L pea gin increased across three impact categories (by 13% for land occupation up to 438% for marine eutrophication), but decreased across 11 impact categories (by up to 207% for human toxicity, and by 80% for global warming).

If pot-ale is processed into DDGS and used as animal feed (Gin+feed scenario), then the net environmental footprint of pea gin decreases considerably, and pea-gin has an equal or lower impact across 12 impact categories compared with wheat-gin (Table 3; Fig. 2). In fact, owing to the high protein content of pot-ale (Table 2) and comparatively low average soybean yields of 3542 kg DM ha−1 yr−1 (Blonk Consultants, 2019), land spared through protein feed substitution equates to two thirds of the land area required to cultivate wheat for gin production. Following allocation of the wheat land footprint between straw and grain, this results in a net land occupation to produce 1 L of wheat-gin of just 0.1 m2·yr (Table 3). Meanwhile, the net land area required to produce 1 L of pea-gin reduces to 1.8 m2·yr after accounting for animal feed substitution. However, whilst the substitution of large quantities of soybean meal by DDGS produced from the protein-rich pea pot ale (Table 7 in Lienhardt et al., 2019) does not fully offset the land area required for pea cultivation, it does result in a net avoidance of 2.2 kg CO2 eq. per L pea-gin (Table 3). A simple interpretation of these carbon footprint results would be that the consumption of pea-gin can mitigate climate change via animal feed co-production through the avoidance of deforestation for soybean production, analogous to claims made for biofuel production (Weightman et al., 2011). Ultimately, however, the land used to cultivate wheat or peas for gin production could be more efficiently used to cultivate crops such as peas, beans or oil seed rape that could be directly used as high-protein animal feed — if the relevant market and regulatory framework was in place to incentivise this. Nonetheless, it is clear that boundary expansion provides a more comprehensive assessment of the environmental efficiency of using peas in place of wheat in gin production, highlighting the significant benefit of additional synthetic fertiliser-N substitution from crop residues and potentially from pot-ale spreading, and animal feed substitution by pea hulls and potentially also by protein-rich pot ale co-products.

3.3. Abatement potential

Results show that maximum abatement potential can be achieved if all pot-ale is converted to DDGS for use as animal feed, confirming results of Leinonen et al. (2018) with respect to whisky by-products. Whilst animal feed substitution is the most likely use of dried pea hulls separated from kernels prior to fermentation, pot-ale is still often treated as a waste product and may not be used to produce animal feed for the following reasons: no demand within short economic transport distances for this liquid waste; high cost and economies of scale required to process it into more versatile (transportable) DDGS; economic incentives to use waste for anaerobic digestion, a “second-best” option for such wastes from a resource and environmental efficiency perspective (Tufvesson et al., 2013; Leinonen et al., 2018). Policy makers and managers keen to promote sustainability should examine opportunities for highest-value use of waste streams (in particular animal feed substitution) before committing to potentially less efficient options from the “green technologies” portfolio.

Globally, approximately 377 million L of gin were produced by the eight largest gin brands in 2017 (Statista, 2019). If production of this quantity of gin shifted from wheat or similar feedstock towards peas or similar legumes such as faba beans, and if pot-ale was all converted into animal feed, the following magnitudes of environmental burden avoidance could be achieved based on extrapolation from the expanded boundary results for Gin+feed in Table 3: 1651 Gg CO2 eq. of GHG emissions, 2.16 PJ fossil energy use; 31.7 Gg N eq. of eutrophication potential and 7,813,049 molc H+ eq. of acidification potential. However, land occupation for agriculture would increase by 63,930 ha. More widely, there is potential for leguminous crops such as peas to substitute wheat and maize in bioethanol production, potentially leading to abatement potentials which are orders of magnitude greater than the aforementioned — over 100 billion L of bioethanol were produced globally in 2017 (Ramesh and Ramachandran, 2019). Global GHG abatement potential could amount to 439 Tg CO2 eq. and eutrophication abatement potential could amount to 8.5 Tg N eq., but the substantial trade-off could be a 17 million ha increase in land appropriated for agriculture.

3.4. Limitations

The identification of the aforementioned environmental outcomes that could arise from substitution of wheat with peas depended on boundary expansion in LCA to correctly identify important interactions across multiple inter-connected systems, and at global scale, as has been shown recently for dairy intensification transitions (Styles et al., 2018b). Whilst we considered nutrient cycling associated with pea versus wheat cultivation and land-spreading of pot-ale as fertiliser, and also possible soybean meal substitution, there remains scope to elaborate the LCA further by developing a full consequential LCA approach. Such an approach could account for, inter alia: changes in entire crop rotation sequences associated with widespread wheat substitution (Nemecek et al., 2015; Styles et al., 2015); a wider range of high protein feeds, and associated co-products, substituted by pot ale (or DDGS); cascading land use change effects associated with cropping and animal feed displacements (Ahlgren and Di Lucia, 2014).

Although producing gin from peas has the potential to reduce land use change in Latin America through displacement of significant quantities of soybean meal, the major trade-off is the requirement for a larger area of cropland for pea production. According to average European land use change factors for cropland expansion (Wernet et al., 2016), the burdens associated with this greater land requirement are comparatively low. However, more work is required to determine a realistic scale for such cropland expansion if peas were widely used for alcohol production. Integrating peas into cereal-dominated rotations would change cropping sequences, and may lead to opportunities for sequence optimisation and yield improvements in following cereal crops that could somewhat offset lower pea yields (Nemecek et al., 2008; Styles et al., 2015; Watson et al., 2017). There are also interesting opportunities for inter-cropping pulses with cereals (Duchene et al., 2017), and cultivation of legumes on Ecological Focus Areas or to diversity crop rotations to increase financial subsidies received under the EU Common Agricultural Policy “Greening” scheme (European Commission, 2011). Pea yields are currently well below their agronomic potential and there is considerable scope to improve them. There remains a need to model the full direct and indirect consequences of legume integration into existing cereal-dominated cropping rotations in Europe, using consequential LCA, in order to better quantify the environmental consequences of substituting cereals with pulses in brewing and distillation.

Finally, more efficient fractionation of starch and protein from pulses could divert protein away from the fermentation process, directly into human foods or animal feeds (Schutyser and van der Goot, 2011). There are also promising advances being made in chemical extraction techniques to isolate pulse protein from pot-ale within the EU funded project TRUE (Horizon Proteins, 2019; JHI, 2019). There remains a need to rigorously explore the environmental sustainability impacts of such options through use of carefully bounded LCA.

4. Conclusions

We undertook simple attributional and expanded boundary life cycle assessment (LCA) of gin produced from wheat and gin produced from peas (Pisum sativum L.). Allocation of system burdens across gin and animal feed co-products indicated that gin produced from peas had a smaller environmental footprint than gin produced from wheat across 12 of 14 environmental impact categories considered, including 12%, 48% and 68% smaller global warming, acidification and eutrophication burdens, respectively. Boundary expansion in life cycle assessment to account for animal feed substitution by co-products further increased the environmental advantage of pea gin overall, owing to larger amounts of protein contained in co-products from pea fermentation. The potential for enhanced soybean meal substitution from use of peas in alcohol production could reduce Europe’s protein deficit whilst potentially avoiding deforestation in Latin America. Land areas potentially spared from soybean meal production partially offset the single major trade-off for pea gin compared with wheat gin; a larger land requirement arising from lower grain yields for peas compared with wheat. Crop rotation (cropping sequence) optimisation, inter-cropping and the potential to cultivate peas in Ecological Focus Areas could mitigate this trade-off. There remains a need to represent these effects within a full consequential LCA in which detailed farm- and landscape- changes associated with the introduction of legumes into conventional (cereal dominated) rotations are elaborated. Our results indicate that substitution of cereal starch with legume starch in alcohol production could be an effective approach to increase the share of leguminous crops in industrialised cropping systems, potentially increasing crop diversity, improving soil health and reducing synthetic N fertiliser requirements. Gin and other alcoholic beverages are well suited for trialling this innovation, owing to small scale, high profit margins and scope for sustainable product differentiation (green marketing). If successful, there is great potential to scale this innovation out to other alcoholic beverages such as vodka and beer, and to scale it up to industrial bioethanol (biofuel) production, with considerable global mitigation potential particularly in terms of climate change and nutrient leakage